Services

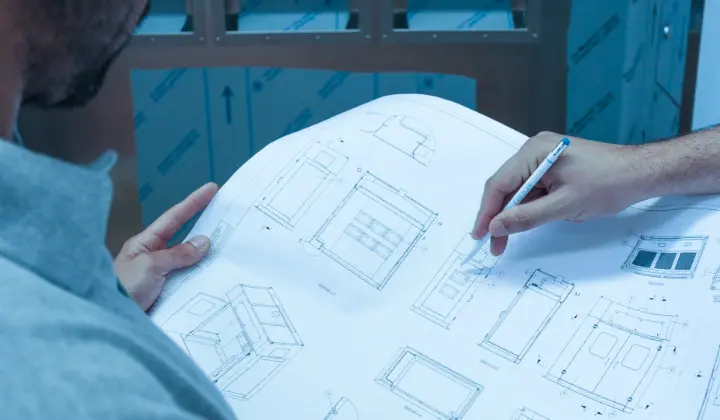

Design

The design of equipment requires careful planning and a thorough consideration of technical and functional

requirements. In particular, Tecninox’s design department applies a series of precise procedures. It defines the

objectives, analyses the market and industry trends, creates a functional diagram of the equipment, including

technical specifications, materials to be used, and necessary components.

Once these data are collected, it develops a detailed project, including software development and electrical design,

develops detailed designs using 3D software, layout and aesthetic design.

If necessary, it creates a mock-up of the equipment to test its functionality and usability, identify defects or areas for

improvement, and make the necessary changes.

Once the design and testing phase is completed, the equipment production begins. The final step involves certifications

of compliance and adherence to applicable safety regulations and requirements.

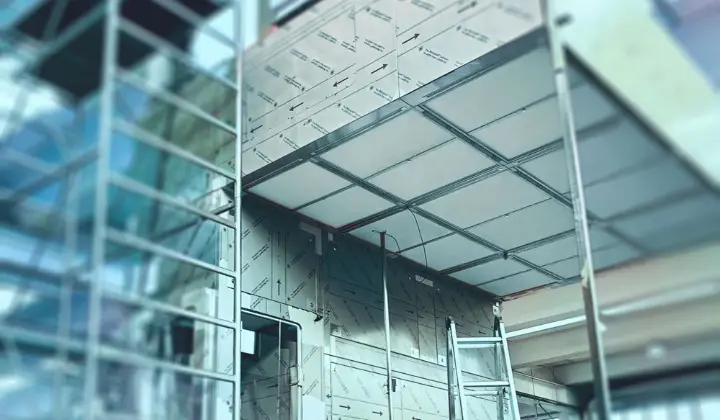

CONSTRUCTION

The construction of equipment requires specific skills and resources. At Tecninox, we follow several key steps in the equipment construction process, including:

- Identifying and procuring the materials and components necessary for the equipment.

- Assembling the various elements following technical drawings and design instructions.

- Verifying that the assembled equipment meets quality standards. This may include functional tests, visual inspections, and safety tests.

After assembly, we conduct acceptance tests to ensure that the equipment performs as expected. These tests may cover aspects such as performance, precision, reliability, and safety. Ensuring full compliance with all applicable directives.

At this point, following the preparation of protocols, the Factory Acceptance Test is carried out in collaboration with the client’s technicians.Preparing the equipment for shipment, including protective packaging.

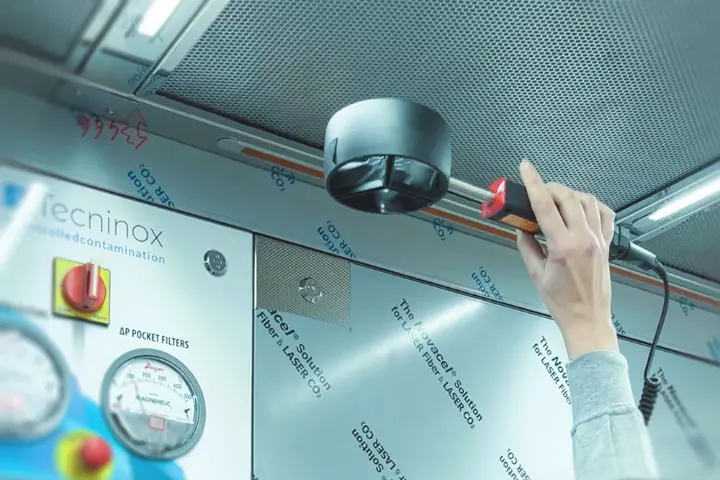

INSTALLATION

The installation of equipment is a critical phase to ensure that the product works correctly and safely.

PLANNING: Before starting the installation, we carefully plan and inspect the area where the equipment will be positioned. We verify the presence of all necessary utilities, such as electricity, network connections, and sufficient space, including the pathways and access for trasporting the equipment to the installation site.

AREA PREPARATION: We ensure that the area is clean and properly prepared.

SAFETY: Before starting the installation, we adopt all safety procedures. This may include the use of personal protective equipment (PPE) and securing the surrounding area.

ASSEMBLY: We assemble the components securely and precisely.

CONNECTIVITY: Typically third parties handle the equipment’s connection to utilities. If required, we can directly manage power wiring, connection to chilled water lines, compressed air, etc.

CONFIGURATION: If the equipment requires specific configuration, we adjust the necessary parameters.

FUNCTIONALITY TESTING: After installation, we conduct functionality tests to ensure that the equipment works correctly.

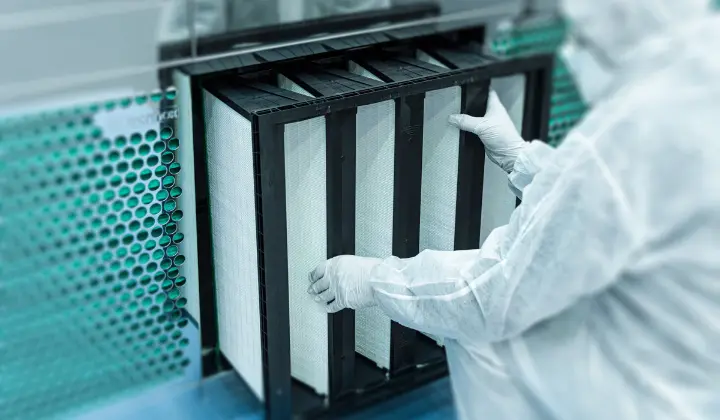

TrAINING

Ensuring that operators are well-trained is essential for both safety and efficiency. Our training programs cover key aspects, including:

STANDARD OPERATING PROCEDURES: Operators learn how to correctly use and maintain equipment in sterile environments.

SAFETY Measures : We provide essential guidelines to protect operators and prevent environmental contamination.

REGULATORY COMPLIANCE: Training includes an overview of industry regulations, such as Good Manufacturing Practices (GMP) and ISO standards.

PREVENTIVE MAINTENANCE: Operators are instructed on routine maintenance and cleaning to ensure optimal performance.

TECHNICAL SKILLS: Hands-on training helps operators master key functions, from parameter adjustments to process monitoring.

CONtaminatION CONTROL : Best practices are shared to minimize the risk of contamination in sterile environments.

EMERGENCY PROCEDURES: Operators are prepared to handle unexpected situations with confidence and efficiency.

DOCUMENTATION & VALIDATION

Documentation and validation of installations are essential in critical environments such as pharmaceutical industry.

Documentation plays a crucial role in creating the necessary record that describe the installation, processes, and procedures. These documents may include schematics, operating manuals, process diagrams, maintenance plans, and more.

Validation ensures that installation functions consistently and meeting predetermined specifications. It includes:

INSTALLATION QUALIFICATION (IQ): This phase ensures that the installation complies with design requirements.

OPERATIONAL QUALIFICATION (OQ): It verifies that the installation works correctly within its specified parameters.

PERFORMANCE QUALIFICATION (PQ): It ensures that the installation works consistently and produces result in line with process specifications.

Installation documentation also covers maintenance plans, detailing regular maintenance and inspections to ensure long-term reliability.

Any modifications to the installation must be documented and validated maintain compliance and system integrity. In regulated industries such as pharmaceuticals, adherence to government regulations and documentation guidelines is necessary.

AFTERSALES SERVICE & SPARE PARTS

The post-sales phase is particularly important for Tecninox.

We promptly to customer inquiries, providing solutions and technical support when necessary.

We address customer complaints effectively, seeking to resolve issues in the best possible way.

We offer technical assistance to support product use and troubleshooting.

UPDATES AND MAINTENANCE

We keep customers informed about updates, bug fixes, or improvements related to the products or services they have purchased.

We gather customer feedback to enhance products, and the overall service quality.

High-quality post-sales service contributes to improving customer satisfaction, strengthens the company’s reputation and fosters customer loyalty.

It plays a key role in part of customer relationship management and must be handled with care.